Fiberglass Reinforced Plastic

The usage of FRP

FRP has typically been used as building materials for bathtubs, water tanks, septic tanks, etc. It is now more widely used in the chemical industry, construction equipment, and shipbuilding thanks to its excellent corrosion resistance, chemical resistance, and lightweight mechanical strength.

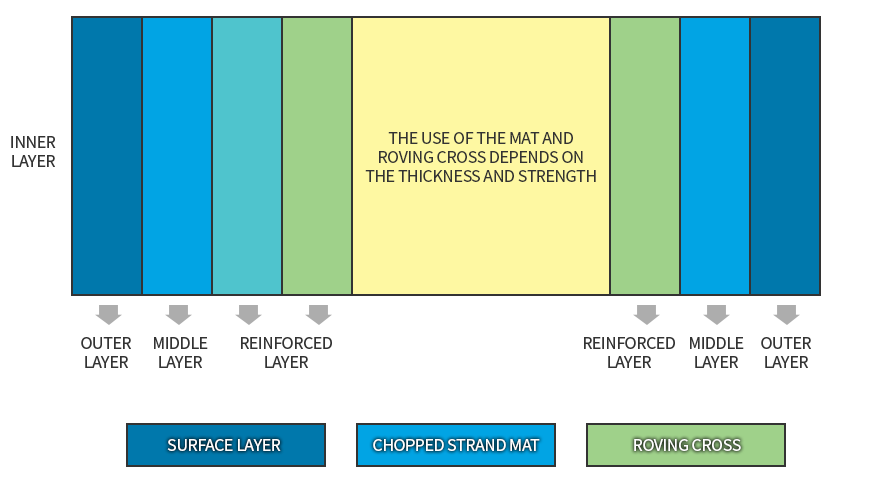

Cross-sectional diagram of FRP

FRP features

- - It is (1/4) lighter than iron and has excellent mechanical strength.

- - It has excellent resistance to corrosion, acid, water, alkali, chemicals, weather, and heat. (heat resistance temperature 40℃ ~ 170℃)

- - It has outstanding thermal insulation and electrical insulation capabilities. (Thermal conductivity: 1/180 of iron)

- - It has no ION elution, and its construction is convenient and simple.

- - It displays strong adhesion, remarkable adhesion to cement, wood, and steel.

FRP production order

- 01

Removal of impurities

Removal of moisture

Removal of oil

Removal of dust and sand - 02

PUTTY

Construction on a curved surface

with RESIN + TARC

- 03

FIRP lamination

GLSASS FIBER(#450): 2 times

+ G/F(#570) 1 time

+ G/F(#450) Construction repeated 3 times - 04

Hardening

- 05

Inspection