Rubber Lining

Product information

- The rubber lining procedure standard inspection criteria

- Safety management manual

- The technical data on rubber lining

- The technical data on the basic theory of the rubber lining

- The current status of the contract on the unit price with POSCO

- The patent for the rubber sleeve for the winding steel sheet

- CATLOGUE (Besides rubber lining)

Rubber Lining

The company, with Korea's largest vulcanization pipes(5,400 X 12,000L), is equipped with the most competitive adhesiveness and durability.

One of the most critical procedures in rubber lining is the vulcanization process.

Rather than using expensive vulcanized rubber rolls, the non-vulcanized rubber rolls with a reasonable price are treated with the lining process. And by adding the most proper pressure and temperature inside the vulcanization pipe, chemical resistant facilities equipped with the outstanding adhesive ability and durability can be created.

The low-temperature vulcanized rubber and non-vulcanized rubber sheets developed by SAEKAPHEN guarantees superior durability when compared to any other rubber sheet.

Also, in the case of construction using German-made rubber (vulcanized rubber), users can carry out maintenance work on-site without having to move the equipment and complete the lining construction rapidly.

Usage

- - Storage tanks (chemical resistance tanks, etc.)

- - Thermal power, hydropower, nuclear power plants, piping lines

- - Chemical devices and equipment: various stirring reaction equipment, continuous pickling equipment

- - Other water treatment carbon filters, VENTURY, CAL ECT TANK, etc.

Storage Tank

The special features of rubber linings

Despite the remarkable advancement of the plastics industry in recent years, SAEKAPHEN KOREA RUBBER LINING is still superior to other companies in corrosion-resistant methods, for it has the following features.- Excellent chemical resistance

- Outstanding adhesive strength

- Economical corrosion resistance treatment

- Reliable construction with high reliability

- Remarkable abrasion resistance

- Convenient repair of defective parts during use

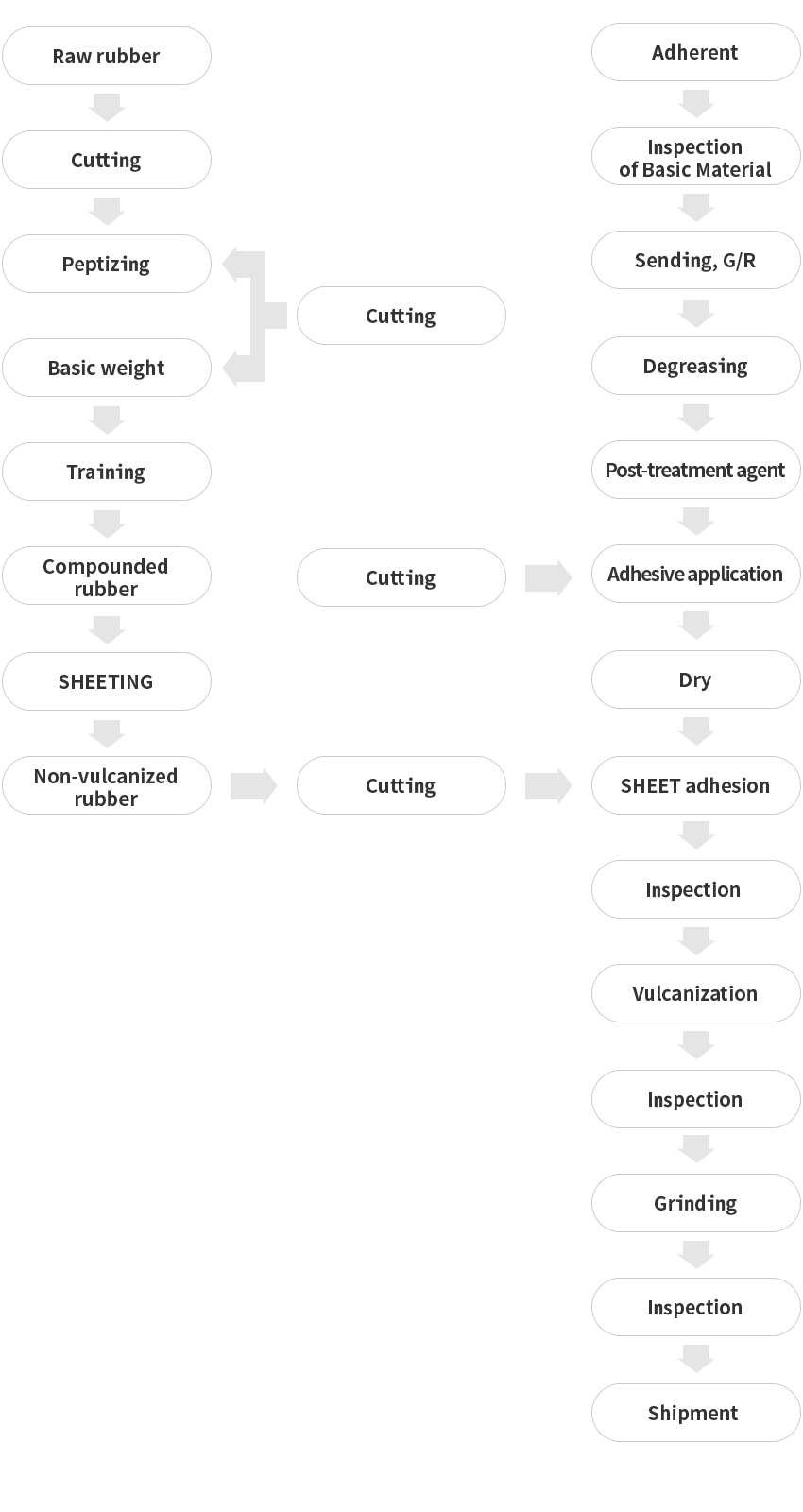

RUBBER LININGS Production Process

The advantages of German-made rubber linings (Construction carried out by the company)

Advantages of Rubber Linings Compared with Polymer Linings

- - Prefabricated sheets (Can be cut into a suitable size and use)

- - Constant thickness

- - Standard thickness 3 mm, 4 mm or 6 mm (Users can choose the suitable thickness among the standard 3 mm, 4mm, 6mm)

- - High permeation resistance (Low permeability)

- - High abrasion resistance (Low abrasion) -> High elasticity

Primary Precured Rubber Lining Materials: The features of primary procured rubber

As precured rubber does not require separate vulcanization treatment, the surface is protected from acid immediately after construction.

| Kerabutyl V | good chem.& therm. (100°C) resistance, good mech. properties, FGD utilization phosphoric acidplants |

|---|---|

| Kerabutyl BS | standard grade wide utilizationrange in FGD |

| Kerabutyl VC | good resistance to hydrochloricacid |

| KerabutylWBC | Oxidizing media, mixedaciSAEKAPHEN KOREA, pickling plant |

| KerapalonHE | resistant to oxidizingmedia, hypochlorite solutions |

Primary of the Lining Material

- - Mixing of raw materials: Mix the rubber material and put it into the machine.

- - Production of rubber sheets: Rubber sheets are produced through a fully automatic system.

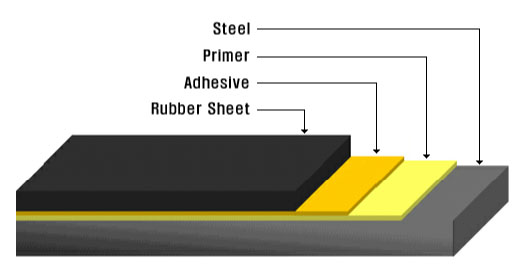

Rubber Lining on Steel Substrate : The construction order using rubber lining

- - For iron plates: iron plate-primer-adhesive-rubber sheet

- - For concrete: Concrete-Epoxy resin-Primer-Adhesive-Rubber sheet