SAEKAPHEN COATINGS

Product information

- Presentation Information Acrobat (Korean)

- Presentation Information (English)

- Catalogue (English)

- Heat Exchangers (Korean)

- Pipelines (Korean)

- Catalytic Corrosion Prevention Coatings (Korean)

- Insulation Coatings (Korean)

- Technology for heat exchanger corrosion and fouling prevention (Korean, English)

- SAEKAPHEN Coatings No.2 (English)

- SAEKAPHEN Coatings No.2 (Korean)

- Product Data sheet (MS word)

- Durability lists (MS word)

- Comparison of the heat transfer coefficients of Carbon steel, Stainless steel, Stainless Steel, and SAEKAPHEN Coatings

- GS Caltex Alkylation-manufactured 156E-504 and tube conditions (After 4 years of usage)

- Sakaflake900 Technology Information

- The tube conditions before cleaning after using GS Caltex #4 diesel 4sus

“SAEKAPHEN KOREA, your best partner for corrosion prevention, is coming to you.”

SAEKAPHEN KOREA promises to bring you maximum profits through cost reduction in the petrochemical and chemical industries, etc.

Highly industrialized developed countries spend trillions of resources every year to solve the corrosion problems in heat exchangers, condensers, storage tanks, and other facilities.One of the typical examples is that they see an increase in maintenance and repair costs due to corrosion. In the case of heat exchangers and condensers, the corrosion problems occurring inside and outside the tubes significantly reduce the efficiency of industrial facilities and thermal efficiency as well. Therefore, the increase in maintenance fees and repair costs have placed significant burden on the industry.

SAEKAPHEN Gmb Hhas opened a new chapter for solving corrosion problem by developing anticorrosive substances.

SAEKAPHEN has remained firmly committed to developing coating materials for over 50 years and has created heat treatment coating technology and low-temperature treatment coating technology. SAEKAPHEN has been widely recognized as a vanguard in the anticorrosive industry, as it has contributed to solving corrosion issues caused by high-temperature steam and chemical reactions.If you are looking for the perfect solution, then our SAEKAPHEN people possess the key know-how acquired from our field experiences.

- The definition of SAEKAPHEN

SAEKAPHEN COATING LIQUID is acquired from liquid thermosetting plastics and applied by letting it flow or using spray technology. - Two coating technologies are applied.

- Heat treatment coating

- Low-temperature treatment coating

Facilities equipped with SAEKAPHEN's technology have been widely used in a wide range of areas such as the petrochemical industry, chemical industry, refrigeration, water treatment, and crude oil distillation, etc.

The features of SAEKAPHEN Coating Substances

- - Has outstanding ability to prevent corrosion

- - Highly resistant to high-temperatures, high-pressured vapor, and other chemical reactions

- - Highly durable even at extremely high temperatures ranging from 100℃ to +200℃

- - Non-conductive

- - Prevents the occurrence of corrosive substances and incrustation caused by chemical reactions inside facilities

- - Considerably lowers the occurrence of fouling factorsby designing new heat exchangers and others

SAEKAPHEN KOREA, the vanguard in the anti-corrosion sector, has been making critical contributions to cost reduction and facility efficiency increase in the domestic industry by signing a license agreement with Germany's Saekaphen GmbH and introducing heat treatment coating facilities.

For example, we at SAEKAPHEN KOREA reduce the initial investment costs as we use low-cost carbon steel to make heat exchangers and apply the SAEKAPHEN heat treatment coating. Otherwise, the initial investment costs would rise due to the use of highly expensive stainless steel or titanium.

In addition, the tube equipped with SAEKAPHEN's heat treatment coating inside does not require any quarterly cleaning process, which consequently has contributed to reducing the maintenance cost or budget for industrial facilities.

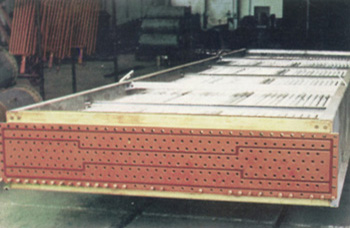

Two welded heat exchangers

When SAEKAPHEN COATING is not applied

When SAEKAPHEN COATING is applied

Comparison of two operating heat exchangers side by side

(Operated for 2 years without cleaning)

(Operated for 2 years without cleaning)

The inner tubes of two heat exchangers

When SAEKAPHEN COATING is not appliedWhen SAEKAPHEN COATING is applied

When SAEKAPHEN COATING is not appliedWhen SAEKAPHEN COATING is applied

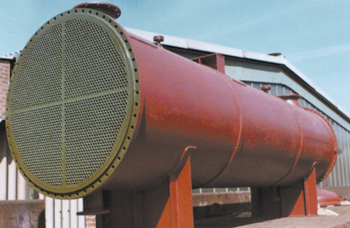

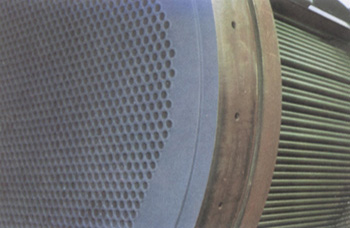

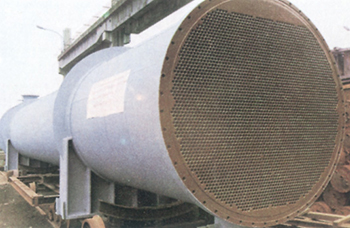

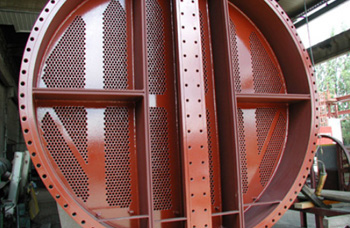

An application example of SAEKAPEN Coatin

circulation water condenser, ordered by Fertilizer Plant, Kuwait

some tube bundles (shell- and tube-side coated)

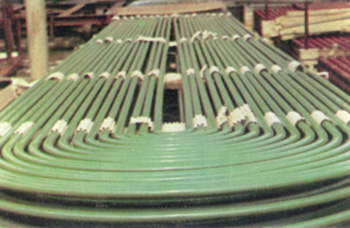

heat exchanger (tube-side coated), ordered by Erdolraffinerie Lingen, Germany

condenser (tube-side coated), ordered by BASF AG, Germany

condenser after tube-side coating

air cooler (tube-side coated), odered by Caltex, Germany

shell-side coating of U-tube bundle

heat cured coating Si 14E of railway container

Bumyang air conditioning equipment coating

Bumyang air conditioning equipment coating

posco carbon filter coating

posco carbon filter coating

storage tanks (flake900)

storage tanks (flake900)

SAEKAPHEN product mix heat cured material

Si 14 E

| colour | dark-green | surface | hydrophob, smooth |

|---|---|---|---|

| dry film thickness μ |

200 | density g/㎥ |

1,39 |

| solid vol-ume ltr./100kg |

27,41 | hardness (konig) lmp./sec |

190 |

| resistance | high acid to slightly alkaline, salt solutions, coling water, gases, organic liquids | ||

| field of application | heat exchangers, air coolers, condensers, evaporators, tanks | ||

Si 14 EG

| colour | red-brown | surface | matte |

|---|---|---|---|

| dry film thickness μ |

250 | density g/㎥ |

1,30 |

| solid vol-ume ltr./100kg |

29,32 | hardness (konig) lmp./sec |

134 |

| resistance | water vapour diffusion, slightly acid a, alkaline liquids and vapour | ||

| field of application | heat exchangers, condensers, condensate containers, thermal degasers | ||

Si 17 E

| colour | red-brown | surface | hydrophob, smooth |

|---|---|---|---|

| dry film thickness μ |

200 | density g/㎥ |

1,44 |

| solid vol-ume ltr./100kg |

30,13 | hardness (konig) lmp./sec |

143 |

| resistance | liquid or gaseous KW, salt solutions, oils, acid to slightly alkaline mediums to PH8 | ||

| field of application | inside coating of tanks for storage of flammable liquids, class of risk AI/AII and B, alphatic hydrocarbon | ||

Si 57 E

| colour | red-brown | surface | hydrophob, smooth |

|---|---|---|---|

| dry film thickness μ |

200 | density g/㎥ |

1,16 |

| solid vol-ume ltr./100kg |

30,10 | hardness (konig) lmp./sec |

200 |

| resistance | high alkaline to acid, all cooling waters incl. brackish-a, sea-water | ||

| field of application | heat exchangers, condensers, evaporators, vessels, water treatment plants | ||

Si 57 EG

| colour | grey-olive | surface | matte |

|---|---|---|---|

| dry film thickness μ |

250 | density g/㎥ |

1,24 |

| solid vol-ume ltr./100kg |

29,52 | hardness (konig) lmp./sec |

120 |

| resistance | water vapour diffusion in alkaline to low acid liquids | ||

| field of application | condensers, condensate containers, degasers a. boilers | ||

SAEKAPHEN product mix cold cured material

HR 60 extra G

| colour | green, red, grey | surface | smooth, glossy |

|---|---|---|---|

| dry film thickness μ |

400-500 | density g/㎥ |

1,50 |

| solid vol-ume ltr./100kg |

60,3 | hardness (konig) lmp./sec |

120 |

| resistance | high alkaline to acid mediums. brackish, sea, a deionized water as well as inorganic salt, solutions | ||

| field of application | tank, silos, filters, vessels | ||

HR 60 extra TG

| colour | red, grey, red-brown | surface | matte |

|---|---|---|---|

| dry film thickness μ |

300-350 | density g/㎥ |

1,40 |

| solid vol-ume ltr./100kg |

33,1 | hardness (konig) lmp./sec |

100 |

| resistance | slightly acid to alkaline aqueous mediums water to | ||

| field of application | desalization plants, condensation tanks, process water tanks, metal pipellines | ||

Sakatonit K 80 LS

| colour | red-brown | surface | satin-finished |

|---|---|---|---|

| dry film thickness μ |

400-max.800 | density g/㎥ |

1,40 |

| solid vol-ume ltr./100kg |

66,4 | hardness (konig) lmp./sec |

|

| resistance | acids to high alkaline mediums, sea-a brackish-water, cooling water a. salt solutions | ||

| field of application | water tanks in power stations, turbine condensers, heat exchangers, coolers, evaporationg a. cooling water pipellnes | ||

Sakaline

| colour | red-brown, white | surface | smooth, glossy |

|---|---|---|---|

| dry film thickness μ |

mind.700 | density g/㎥ |

1,55 |

| solid vol-ume ltr./100kg |

64 | hardness (konig) lmp./sec |

|

| resistance | water to 100℃ a. temperature drop to the surface, temperature difference up to 80℃ | ||

| field of application | boilers a other water heaters for drinking a. nondrinkable water, KTW recommen-dation a. all rangs of cold a. heat water | ||

Sakaflake 1042

| colour | black | surface | matte |

|---|---|---|---|

| dry film thickness μ |

700-3000 | density g/㎥ |

1,42 |

| solid vol-ume ltr./100kg |

46,09 | hardness (konig) lmp./sec |

ca.120 |

| resistance | aggressive mediums of chemical industry, high acid ranges a high temperatures | ||

| field of application | flue gas desulfurizing plants, tanks, pipelines, tanks vessels, pipes | ||

Sakaflake 1052

| colour | black-grey | surface | matte |

|---|---|---|---|

| dry film thickness μ |

700-3000 | density g/㎥ |

1,43 |

| resistance | slightly alkaline to high acid mediums, sea-water, inorganic salt solutions, fue gas, electrostatic derivation ability | ||

| field of application | storage tanks, containers, flue gas channels, process tanks, washing towers, gas purifying plants | ||

Sakatar D extra

| colour | black, red-brown | surface | matte |

|---|---|---|---|

| dry film thickness μ |

mind.500 | density g/㎥ |

1,5 |

| solid vol-ume ltr./100kg |

79,5 | hardness (konig) lmp./sec |

74 |

| resistance | good chemical resistance, high temperature load, higher water vapour diffusion | ||

| field of application | power stations, nuclear power stations, cooling water pipelines, tanks | ||